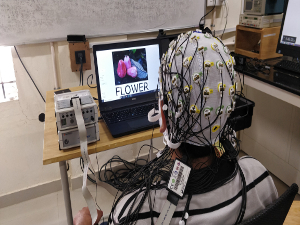

Brain Machine Interface Systems lab at IIT Palakkad focuses on the development of Brain Machine Interface (BMI) systems, which offers alternate ways to augment a wide range of human activities such as locomotion, cognition and perception. Our BMI research aims to design and implement Electroencephalography (EEG) based BMI systems using signal processing and machine learning techniques to decode the associated neuronal signatures corresponding to various mental tasks. The laboratory is equipped with 64 channel actiCHamp EEG amplifier (Brain Products) with data acquisition software, Emotive Epoc+ and MUSE 2 Head band for data acquisition, monitoring and analysis, providing an interactive environment for experimental research.

Research Facility

IIT Palakkad has set up the Central Instrumentation Facility and Central Micro-Nano Fabrication Facility with the primary objective of supporting the research activities of its faculty, Ph.D scholars and Postdoctoral researchers. The facilities will house a wide range of sophisticated analytical and fabrication equipment, maintain them and ensure a fair utilization among the research community.

Medium force fatigue testing machine that is servo-hydraulic built for static and dynamic testing of materials at various frequencies and temperatures is available in design lab. The test setup has 3 section furnace to heat up to 1000°C.

The following tests can be done on the machine

Design (contact mechanics) lab is equipped with a twin disc rolling contact fatigue (RCF) tester with scope for real time assessment of the tests. RCF is the phenomenon by which the durability of the contact surfaces is reduced due to repeated contact under rolling/sliding contact conditions. The test rig is used to simulate such contact stresses between any mating parts, eg. bearings and gears. The system is equipped with an accelerometer g sensor with 1g limit.

Manufacturing research lab has advanced materials processing facility consists metal additive manufacturing (AM) system, the method that relies on a digital data file being transmitted to a machine then builds the component. The technology helps us make complex parts from various engineering materials with high standards of quality that are not possible using conventional manufacturing methods.

The experimental facility consists systems for studying flames and laser diagnostic setup. The lab is equipped with a high pressure compressor (45 bar), 1 m3 air receiver, air-dryer with flow lines for delivery to the setups in the lab. Fuel supply from a cylinder bay is also available. Flow control is achieved uing Alicat mass flow controllers (MFC) of various ranges.

This facility is used for both teaching and research in the field of water resources engineering. Students get practical experience on the different concepts of fluid mechanics, hydraulics and water resources engineering. Studies on open channel flow, pipe flow, coastal protection and hydrology can be done in this laboratory.

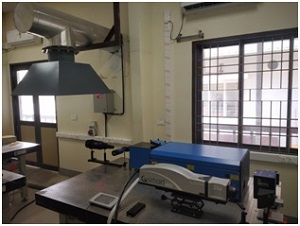

Environmental Engineering lab supports both teaching and research in the field of water quality assessment, water and wastewater treatment, analytical chemistry, and microbiology. The laboratory is well furnished with incubators, fume hood, balances, centrifuge, shaker, pH meter, COD digester, drying oven, and muffle furnace.

Geotechnical engineering is a branch of civil engineering that deals with the engineering behaviour of earth materials. Geotechnical engineering laboratory of civil engineering department at IIT Palakkad is equipped to perform all the necessary tests for the characterization and determination of geotechnical properties of soils, geosynthetics etc. along with several advanced testing facilities.

Material Testing Laboratory is used for material related testing particularly for the concrete. The construction materials laboratory at IIT Palakkad has been developed to cater to both undergraduate teaching as well as advanced research, mostly related to building materials.